Description:

The SurfPurge 12 is a mixture of special cleaning salts, formulated for cleaning Aluminum, NiP and Cobalt, Chromium, Gould in Hard Disk Drive or Semiconductor devices.

Application:

SurfPurge 12 are mostly used for cleaning metal surfaces in fabrication of Hard Disk Drive or during Semiconductor fabrication process. This solution is especially effective for removing ionic particles, traces of heavy metals and for pH sensitive surfaces such as Aluminum. SurfPurge 12 is also used for cleaning surfaces of NiP and Cobalt during manufacturing of Hard Disk drives. For more information, please contact us.

Cleaning process:

- Process temperature is about 23 to 28 degrees C.

- Mechanically agitating the cleaning solution or performing the cleaning process within a Sonication or use of spray system is highly recommended.

- Initially soak wafers or disks in a 1:50 (SurfPurge 12: Di-water) dilution of SurfPurge 12 for 30 seconds in order to get rid of all loose particles. This step will also increase the bath lifetime of the actual concentration of your cleaning solution in your cleaning process.

- After the above initial step, expose the wafers or disks to SurfPurge 12 solution in a 1:10 dilution (SurfPurge 12: Di-water) for 40 to 60 seconds.

- Rinse your wafers or disks several times with warm Di-Water to get rid of cleaning solution residues.

- Dry your wafers or disk immediately to eliminate airborne contamination.

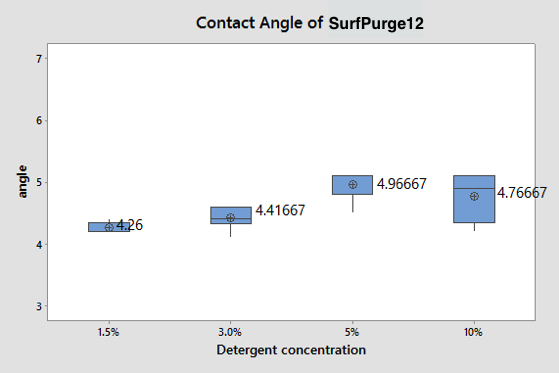

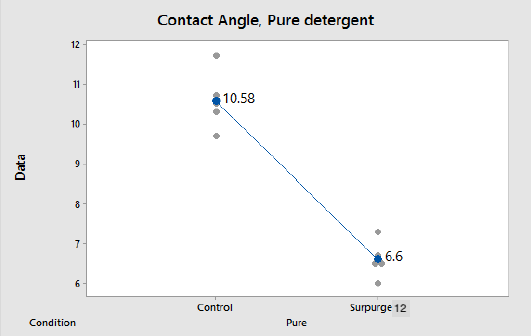

- Very low contact angle, about 6 for the main solution and <2 for 5% diluted solution

- Operation temperature is between 23 to 28 degree C

- No corrosion on metal surface after cleaning process

- High Di-water rinsing time

- Extremely effective in removing particles