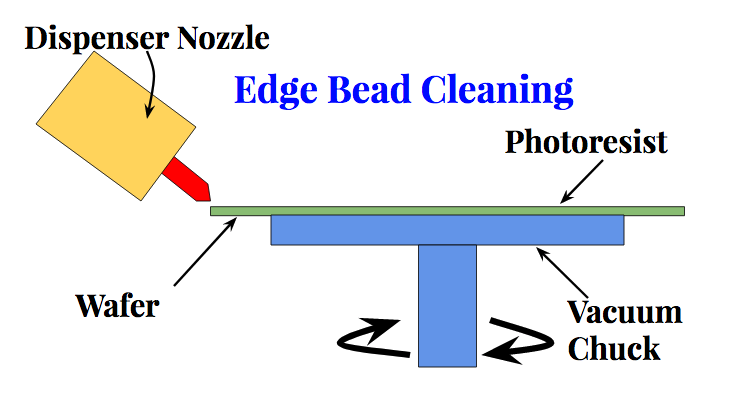

The spin coating of photoresist, anti-reflective or polyimide coating on microelectronic substrate often results in the formation of what is known as edge bead. This refers to the unwanted accumulation of the coated material at the outer edges of the substrate in form of a bump. These accumulations may also wrap around the edge of the substrate and as a result may contaminate the back-side edges of the substrate as well. If the edge of wafers are not cleaned, the dried particles or photoresist residues can flak off, causing particle contamination and other problems in subsequent manufacturing and process steps. Consequently, the unwanted residues on the outer reaches of the substrate should be removed by using a stream of high purity solvents to clean and to level the edges to the same thickness as the rest of the substrate surface area.

Solexir is presenting two series of Edge Bead Remover with a wide range of selectivity:

- Solexir EBR-500 series, with low density and extremely effective in cleaning thick photoresist strippers

- Solexir EBR-520 series, with medium range density, viscosity and higher solubility applicable to situations where films contain different polarities.

- None toxic

- Water Soluble

- Room temperature operation

- Fast particle and residue cleaner

- Optimized for density and viscosity

For more details please see the Solexir Edge Bead Removals products line.