Owing to its electrical conductivity and optical transparency, Indium-Tin-Oxide (ITO) is one of the most widely used Transparent Conductive Oxides (TCO) for LCD displays, touch panels, solar cells and other related applications. It is typically made of 90% indium (III) oxide (In2O3) and 10% tin (IV) oxide (SnO2), by weight. Although a minor component, the SnO2 is typically more difficult to etch than In2O3 and, as such, it is more likely to remain as post-etch residues if the conditions are not fully optimized. ITO films containing only amorphous phase are also more readily etched than those containing different degrees of crystalline phase.

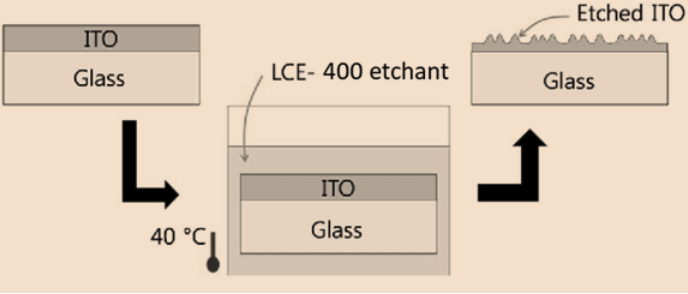

ITO etchants are composed of hydrochloric and/or oxalic acid as stand-alone or in combination with surfactant and other additives. They are typically used under mild heated conditions (30-50˚C), displaying etch rates of ~ 400-2000 A/min. Additives provide the following benefits:

- etch uniformity

- etch rate adjustment

- bath life improvement

- etch selectivity enhancement

- edge profile tapering

Solexir standard ITO offerings consist of following five products, identified as liquid crystal etchant (LCE) 100-500, which are formulated to meet the requirements of most applications:

| PRODUCT NAME | PRIMARY COMPONENTS |

| LCE- I00 | Hyrochloric-nitric based |

| LCE-200 | Hydrochloric-ferric chloride based |

| LCE-300 | Hydrochloric-oxalic acid based |

| LCE-400 | Hydrochloric-nitric-ferric chloride based |

| LCE-500 | Oxalic acid based |

For product recommendation and technical support, please contact Solexir